Search Product

Search here for what you are looking for:

- Hot:

Send Inquiry

If you have any questions about our products, you can submit the form and we will contact you as soon as possible

Search here for what you are looking for:

If you have any questions about our products, you can submit the form and we will contact you as soon as possible

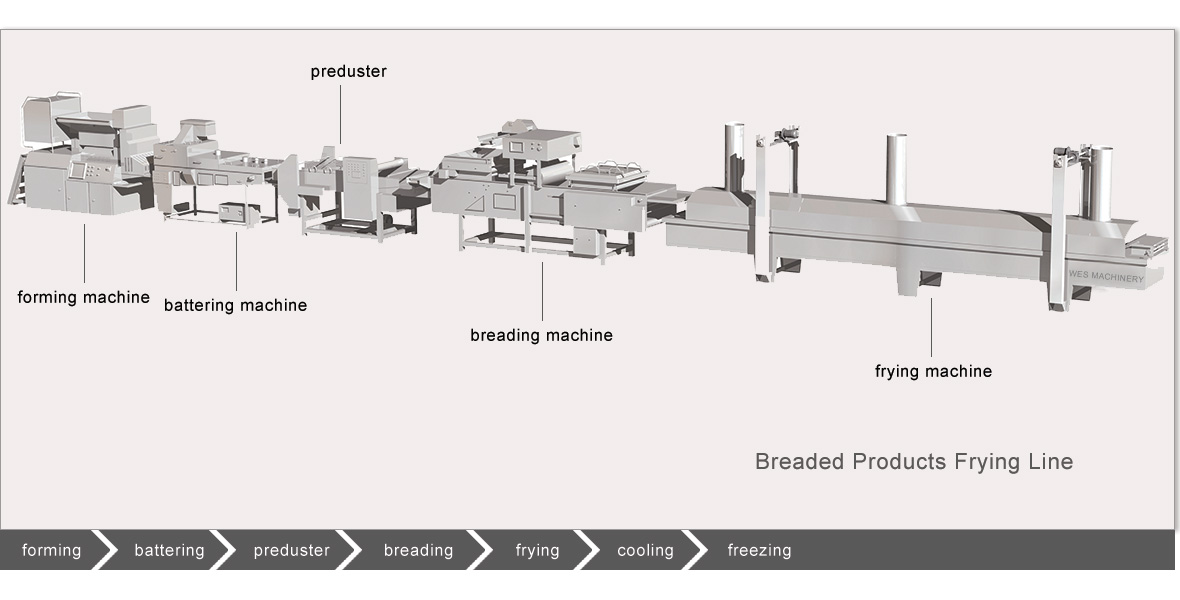

This line is used for chicken nuggets and breaded products. The whole production line including forming machine, battering machine, preduster, breading machine, frying machine, cooling machine and freeze machine. Realized the full automation production operation. Minimize man-made factories, in order to ensure maximum efficiency for more high quality products.

☆ Forming machine: Machine can automatically fulfill the procedures such as the filling of the minced meat, forming, paster, outputting, etc. The forming speed can be adjusted.

☆ Battering Machine: The products can be evenly coated with batter when passing two batter curtains on the top and the bottom bath filled with batter.

☆ Preduster: The bottom of the product can be evenly coated when passing the conveyor loaded with flour. Unique-designed conveyor sprinkles flour evenly on the products' curtain, which ensures an even, equal-portion and thick or thin coating on products.

☆ Breading machine: Excellent cyclation system ensures the maximum retention of the crumbs. Applies not only for the fine crumbs, but also for rough crumbs.

☆ Fryer: Double belt conveyor , a conveyor belt - depending on application partly Teflon - transports the products through the heated oil. The hold-down conveyor which can adjusted in height, ensures the products remain immersed. A built-in slotted screen filter removes floating (surface) sediment out of the fryer. The internal oil circulation is controllable to ensure optimum temperature distribution and effective sediment removal.